“Taits Consulting has adapted the critical concept known as the Golden Thread to help leaders ensure that safety controls are robust, integrated and effective throughout their organisation”

Safety in the WA mining industry is a key focus for leaders, given the inherently hazardous nature of mining operations.

The industry often operates in remote and extreme environments where critical risks such as uncontrolled energy releases and mobile equipment collisions are ever-present.

Managing these risks is not only a legal requirement but a moral responsibility to ensure the safety of workers and the sustainability of operations.

Taits Consulting has adapted the critical concept known as the Golden Thread to help leaders ensure that safety controls are robust, integrated and effective throughout their organisation.

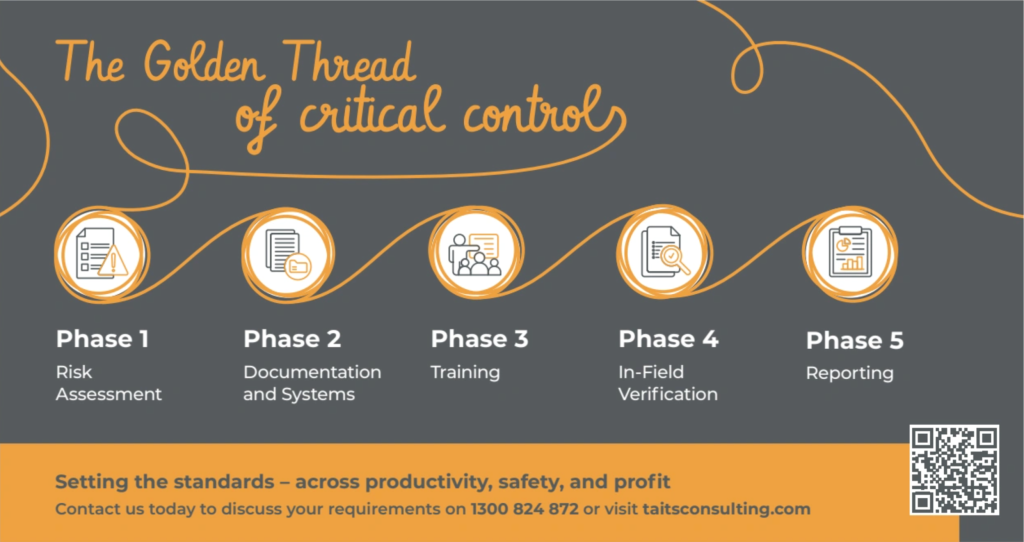

The Golden Thread is an analogy that illustrates the continuous connection and alignment of critical controls across five essential phases: Risk Assessment, Documentation and Systems, Training, In-Field Verification, and Reporting.

This approach ensures that every critical control is consistently applied and verified, bridging the gap between safety theory and real-world practices. When done effectively, it moves safety management from a siloed mindset to a comprehensive, integrated framework.

The first step in managing critical risks is a comprehensive risk assessment. The Golden Thread starts here by identifying the potential hazards, their consequences, and the controls required to mitigate them.

Importantly, risk assessments must be dynamic, and the outcome of these assessments must directly inform every subsequent phase. If risk assessments are not thorough, are incomplete, or not regularly updated, the Golden Thread is broken from the start.

Once critical risks have been identified, it is crucial to document the critical controls clearly and ensure that proper systems support their implementation. This step involves integrating critical controls into documentation within the Safety Management System. However, having documents alone is not enough. The Golden Thread in this phase also ensures critical controls are embedded into daily operational processes and systems.

Even the best risk assessments and systems are purposeless if workers are not adequately trained. Training must focus on ensuring that personnel not only understand the critical controls but are also competent to implement them in the workplace. The Golden Thread in this phase ensures that training programs are specifically aligned with the critical controls identified in the risk assessment phase.

Effective training should be more than just box-ticking exercises; it should build a genuine understanding of why certain controls are in place and what the consequences are if they fail. Workers should be empowered to recognise when controls are not functioning and take the necessary corrective action.

In-field verification is where plans meet practice. This phase involves verification checklists, audits, and/or direct observation by leaders to confirm the critical controls are functioning as intended in the field.

The Golden Thread ensures that verification is not a one-off exercise but an ongoing process. Every verification activity should tie back to the risk assessment, ensuring that what was identified on paper is being executed in practice.

This phase is essential for identifying any discrepancies

or weaknesses in the system before they lead to incidents. By continually checking that critical controls are functioning effectively, companies can maintain alignment across all phases of the Golden Thread.

The final phase of the Golden Thread is reporting. This involves systematically capturing data from verification activities, as well as incident and hazard reports, to feed back into the risk management cycle. Reporting ensures that any shortcomings in critical controls are identified, analysed, and corrected in a timely manner. The more comprehensive and timelier the reporting, the stronger the Golden Thread becomes, enabling continuous improvement in managing critical risks.

This approach is more than just theory. When applied consistently, it can drive significant improvements in safety outcomes. However, its success hinges on strong leadership, a commitment to continuous improvement, and a willingness to invest in systems and people. When these elements are in place, the Golden Thread weaves a robust fabric of safety that spans from planning all the way to execution and review.

Taits Consulting works with organisations in the WA mining industry looking to take their safety systems to the next level, by understanding and implementing the Golden Thread which is the difference between merely meeting compliance requirements and truly safeguarding workers in hazardous environments.